THP3000i [Intermittent TTO]

- Summary

- Specification

- Demo video

A new-generation standard model intermittent TTO with

improved productivity and reliability at manufacturing sites

THP3000i

- [Maximum printing speed]

380 mm/sec (22.8 m/min) - [Maximum printing area]

53 mm(W) x 75 mm(L)

- Print resolution 300dpi

- Auto calendar

- Barcode printing

- QR code printing

- “EUI2” by SD card

The intermittent TTO "THP3000i" is a new generation machine that is a complete model change of the long-selling intermittent TTO model "THP301 series".

In addition to being compatible with our new generation printer standard "Generation 3", it is equipped with new functions that further improve productivity and reliability, meeting the needs of manufacturing sites. Designed with compatibility with conventional machines in mind, it can be easily integrated into existing lines.

Mainly suitable for integration into intermittent packaging machines such as vertical pillow packaging machines.

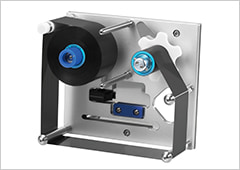

Cassette unit with an automatic locking function

We have adopted a cassette system that has been well received in conventional models. This enables quick replacement of thermal ribbons, contributing to reducing downtime. Additionally, the cassette unit is equipped with a new "automatic locking function," a first for this machine. When the cassette is mounted, it automatically locks, preventing inadvertent opening and facilitating easy attachment and removal of the cassette.

Equipped with new functions that meet the needs of manufacturing sites

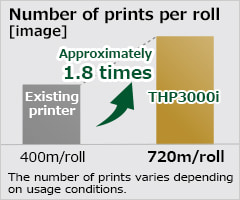

With an increase in ribbon winding capacity by 80%, downtime is significantly reduced

The thermal ribbon now supports up to 720 meters in length (compared to 400 meters in previous models). By extending the length of compatible ribbons, the frequency of ribbon replacement is reduced, contributing to improved productivity in manufacturing facilities.

Print head can be replaced with one-touch

The print head attachment/detachment mechanism uses a magnetic type. One-touch replacement is possible, greatly improving the work efficiency of print head replacement. There is no risk of losing parts such as screws during work, improving safety at the production site.

High durability and wire-saving design for improved reliability

Adoption of a flexible substrate with excellent flexibility improves the durability of the head cable. Noise resistance is enhanced by a wiring-saving design that significantly reduces the number of wires and by the use of differential signal systems for various signal lines. Overall equipment reliability has been improved

Stable initial printing even at low temperatures

Equipped with a preheat function that ensures stable printing from startup, even in cold climates or at the start of the morning workday in winter. Even a thermal ribbon with a high melting point can quickly reach a predetermined temperature. This makes it easier to maintain the condition of the head, enabling more stable operation.

Please note that the images provided are for the THP2000c model.

Improvement in print quality and stability

Smooth drive is achieved by adopting the next generation Gen3 control and calculation device. In addition to our new technology DEM-Tech, improved line speed followability of ribbon feed contributes to overall improvement and stability in printing quality.

Main body design considering compatibility with previous models

The main body of the THP3000i is designed with consideration for compatibility with previous models [THP301 and THP301L]. As the mounting brackets from the previous model "THP301 series" can be reused, it facilitates easy installation onto existing lines. Additionally, minimizing disposal during model upgrades contributes to the efficient utilization of resources.

Color touch panel controller “EUI2”

The color touch panel controller "EUI2" common to EDM is used for the operation interface. The easy-to-understand hierarchical system and large color LCD allow comfortable operation.

[feature]

- Easy operation, item switching, and parameter setting

- Large letters and icons on the top (operation) screen clearly display the machine's operating status

- Item search function by item name and key word

- Displays the preview in the actual print size

- SD card is used as the recording media

Printing sample

[Packaging form]

- Vertical pillow packaging

- Sachet packaging

[Printing data]

- Best-before date

- Expiry date

- Date of manufacture

- Production time

- Lot number

- Factory mark

Specification

| Model | THP3000i |

|---|---|

| Type | Intermittent |

| Print method | Thermal transfer |

| Printing resolution | 300dpi (12dots/mm) |

| Maximum printing speed | 380 mm/sec (22.8 m/min) |

| Maximum printing area | 53mm(W) × 75mm(L) |

| Font size | 24-96 dots (24 size/font) |

| Print extension | Date Format, Date Stamp with Offset, Time, Shot Count, Shift Code, Custom Code |

| Barcode | EAN8, EAN13, ITF, CODE39, CODE128, GS1-128, GS1 DataBar |

| 2-dimensional code | QR code, Micro QR code, DataMatrix |

| Data memory | SD card |

| Thermal printer ribbon | 720 m/roll (Max.) |

| Interface port | RS232C / RS422 / Ethernet (option) |

| Power supply | AC100V/200V, 50Hz/60Hz |

| Power consumption | 420W |

| Body weight | 6.8kg |

| Dimensions | 210mm(W) x 183mm(H) x 272mm(D) |

| Configuration | Main body / Power supply box / EUI2 |

| Usage Environment | Temperature : 5℃-40℃ Humidity : Under 90%RH (no dew condensation) |

| Option | Item editing software (GIE) |

※The above specifications may differ depending on the usage conditions, mounting conditions, use of mounting brackets, environment, etc. Specification and other information are subject to change without notice.

Main unit and related software correlation diagram