THP600 series [Desktop TTO]

- Summary

- Problem-solving

- Specification

- Demo video

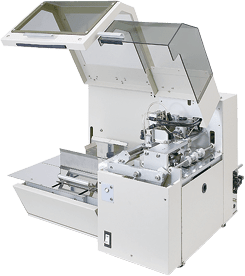

Desktop TTO for quick and easy printing on empty bags

THP600 series

- [Maximum printing speed]

280 mm/sec - [Maximum printing area]

[THP621] 53mm(W)×250mm(L)

[THP641] 105mm(W)×250mm(L)

- Print resolution 300dpi

- Auto calendar

- Barcode printing

- QR code printing

- “EUI2” by SD card

THP600 series are the most appropriate desktop thermal transfer overprinter for directly printing on the empty bag in offline. They offer high resolution printing, so they enable clear and readable printing for characters such as dates, barcodes and logos. They also can print a lot of information at once.

Advantage of the THP600 series

01

Clear printing

A high-resolution thermal head of 300dpi is adapted, enabling clear printing. In addition to dates, it also supports logos, various barcodes, QR codes, and GS1 DataBar.

02

Large print area

Lineup of 2 models with print width of 53 mm (THP621) and 105 mm (THP641). With the THP641, it is possible to directly print large area of up to 105mm x 250mm.

03

Easy operation/ setting

The EUI2 color touch panel is used for operation and setting, and the easy-to-understand hierarchical method makes it easy to operate, switch items, and set parameters.

04

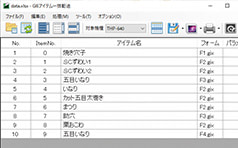

Easy item creation

Anyone can easily create and edit printed content using the editing software GIE. Depending on your PC, English, Chinese, and Arabic are also possible.

05

Easy maintenance

The transparent cover allows you to see at a glance the status of the printer, the bag, and the remaining amount of thermal ribbon. No tools are required to replace the thermal head.

06

Rich lineup of thermal ribbons

We will propose the optimum thermal ribbon according to the material of the bag and post-processing after printing.

Productivity is further improved by using an automatic feeder.

The "VF601" is a dedicated empty bag automatic feeder for automating the bag supply of the desktop thermal transfer overprinter "THP600series" . The stable supply of bags by EDM’s unique supply mechanism realizes automation of offline printing work, dramatically improving work efficiency.

Color touch panel controller “EUI2”

The color touch panel controller "EUI2" common to EDM is used for the operation interface. The easy-to-understand hierarchical system and large color LCD allow comfortable operation.

[feature]

- Easy operation, item switching, and parameter setting

- Large letters and icons on the top (operation) screen clearly display the machine's operating status

- Item search function by item name and key word

- Displays the preview in the actual print size

- SD card is used as the recording media

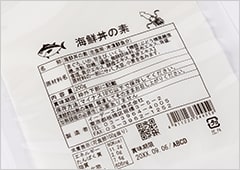

Printing sample

For OPP bags, nylon plastic bags, aluminum deposited bags, aluminum bags, paper bags, flat bags, 3-side sealed bags, zipper bags.

Applicable workpieces vary depending on the thickness, shape, and material of the bag. Please contact us for details.

EDM's desktop TTO THP600 series solves your problems!

Any problems with printing product information

on empty bags?

How is it printed on the empty bag? If it is preprinted or displayed by a label, it might be worried about the following.

- It might not handle the cost of labels such as label price, label disposal and so on.

- There are many kinds of products in small quantities, as well as many types of packaging materials, which makes stock management difficult.

- In case the display contents such as the place of origin change, it takes time and cost to correspond.

- There are some risks, for example someone peels off a label and counterfeits it.

But, these problems are solved

by direct printing with the THP600 series

Benefits

![]()

Contribute to reduction in the amount of film and eliminate waste of it.

In the case of many kinds of products in small quantities, packaging materials can be reduced by making the packaging film the same size and printing different information directly. Material loss does not occur even when the displayed contents are changed.

![]()

Easily change displaying product information.

Since the Thermal transfer overprinter can print the required content in the required number at the required time, the displayed content can be changed quickly.

![]()

There is no risk of the label being peeled off or counterfeiting.

It helps prevent counterfeiting by relabel. There is also no risk of accidentally peeling the label.

![]()

Reduce the cost of labels.

It is possible to reduce label fee, disposal costs of label mounts and downtime in changing labels.

There is also an advantage in changing the hot foil to THP600 series

![]()

The date is automatically updated, so it does not take time.

It doesn’t need to change the types, so there will not get the date wrong. Also, if it is compatible with “Auto Calendar”, the expiration date will be calculated automatically, so there will be no mistakes in calculation.

![]()

Realizes safer and higher quality printing.

Since printing is performed without applying pressure, there is no need to worry about pinholes compared to hot foils. In addition, printing with a clear and easy-to-read thermal transfer overprinter further improves product reliability.

Specification

| Model | THP621 | THP641 |

|---|---|---|

| Type | Desktop thermal transfer overprinter (TTO) | |

| Print method | Thermal transfer | |

| Print resolution | 300 dpi (12 dots/mm) | |

| Maximum print speed | 280 mm/sec (9 steps variable) | |

| Maximum print area | 53 mm(W) x 250 mm (L) | 105 mm(W) x 250 mm (L) |

| Product size | Width : 70 mm to 320 mm Length : 130 mm to 350 mm |

|

| Font size | 24-96 dots (24 size/font) | |

| Print expansion | Date Format, Date Stamp with Offset, Time, Shot Count, Shift Code, Custom Code | |

| Barcode | EAN8, EAN13, ITF, CODE39, CODE128, GS1-128, GS1 DataBar | |

| 2-dimensional Code | QR code, Micro QR code | |

| Data memory | SD card | |

| Thermal printer ribbon | 400 m/roll (Max.) | |

| Interface port | RS232C / RS422 / Ethernet | |

| Power supply | AC85-132V/170-264V・240VA・50Hz/60Hz | |

| Weight (main body) | 20.0kg | 23.0kg |

| Dimensions (mm) | 310(W) x 345(H) x 471.4(D) [Excluding feeding table] |

|

| Usage Environment | Temperature : 5℃-40℃ Humidity : Under 90%RH (no dew condensation) |

|

| Option | Item editing software (GIE) | |

※The above specifications may differ depending on the usage conditions, mounting conditions, environment, etc. Specification and other information are subject to change without notice.

Related products to help improve

the quality and efficiency of displaying on empty bags.

The automatic feeding machine ”VF601”

Item Batch Transfer Software ”IBT”

Labeller for bags "LMFe6000-FJ"

![printing sample [zipper bags]](https://www.edm-net.co.jp/img/img_thp600_zippersam_s.jpg)