PCi500 [High-performance date printing inspection machine]

- Summary

- Specification

- Demo video

Meet the diverse needs of packaging sites for print inspection

PCi500

- Color camera /

color lighting - Barcode

verification - Simulation inspection function

- Full image saving function

- Simultaneous inspection with 2 cameras

- 10.1 inch

color monitor

"PCi500" is a high-performance model of the "PCi series" print inspection machine, which features excellent print inspection functions and ease of use at packaging sites.

Color camera / color lighting

The PCi500 uses a color camera and color lighting to capture inspection images. Even if there is a pattern on the background of the print or the background is multicolored, it is possible to extract only the characters to be inspected and cut out the characters suitable for inspection.

Furthermore, by utilizing the new function "Automatic Lighting Adjustment Function", you can realize even more optimal character cutting.

If there is a pattern in the background of the print

Printing example

Black and white camera

(white lighting)

PCi500 : Color camera

(blue lighting)

If the background of the print is multicolored

Printing example

Black and white camera

(white lighting)

PCi500 : Color camera

(white lighting)

Barcode/2D code inspection

PCi500 is equipped with various barcode and 2D code reading functions and is compatible with the following inspections.

Verification inspection : Compare the registered data and the imported image.

Reading inspection : Inspects readability.

Quality inspection (barcode only) : Inspects the captured image for chipping.

Compatible barcodes

[verification inspection / reading inspection / quality inspection]

EJAN8 / EAN13 / UPC-A / UPC-E / ITF / NW-7 (CODABAR) / CODE39 / CODE128 (GS1-128)

Compatible 2D code

[verification inspection / reading inspection]

DataMatrix / QR code

※Barcode/2D code inspection may or may not be possible depending on the camera installation situation and the printing status of the object to be inspected. We recommend testing in advance with the specifications you will use.

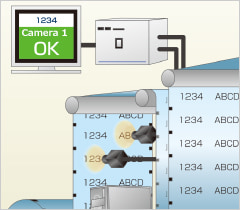

Simultaneous inspection of up to 2 cameras possible with 1 controller

PCi500 allows simultaneous inspection of up to 2 cameras with 1 controller. Space and cost savings can also be achieved.

Equipped with a 2ch independent trigger, it can handle different image capture timings, and the dual-screen display monitor allows you to check the shooting content of two cameras at the same time.

Example of inspection with two cameras (image)

- Inspection of different printing locations (2 locations) on one product

- Print inspection of the same content on 2 lines

- Printing inspection and label pasting confirmation on horizontal pillow packaging machine

- Multi-line printing inspection on deep drawing packaging machine

6-step easy operation system

The basic settings only require the following 6 steps.

- Image import

- Preprocessing settings

- Inspection frame settings

- Character string settings

- Character cutting settings

- Dictionary settings

Each setting screen is structured in an easy-to-understand manner, and you can easily create items by following 6 steps without having to remember anything difficult.

New features only available on PCi500

that are useful at manufacturing sites

Automatic lighting adjustment function

The "Automatic Lighting Adjustment Function" newly added to the image capture settings is a function that automatically selects the most suitable color for the object to be inspected from 224 selectable lighting colors with a single button. This function realizes character extraction that maximizes the benefits of color lighting.

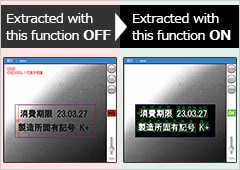

Dynamic binarization function

The "dynamic binarization function" newly added to the processing settings automatically performs optimal binarization for each inspection image, eliminating uneven gradation-like patterns within the inspection image. This function allows you to properly extract characters even when there is a shadow (this function is effective for inspection when the background is white and the characters are black).

Other common features of the PCi series

Thermal printer linkage function

The PCi series pursues operability and ease of use at packaging sites, and is equipped with a function that works with all of our thermal printer models. You can easily switch items, set expiry dates, and synchronize the calendar timer (internal clock).

All-in-one model specialized for integration into packaging machines

It is an all-in-one model that includes the necessary components (main unit, camera unit, monitor) for integration into the packaging machine, making it easy

to integrate into the packaging machine.

We also took into consideration space-saving features when connected to a printer, and paid particular attention to the design to fit in any worksite environment.

Achieve essential precision to maintain productivity

High test accuracy is not just good. The PCi series achieves "essential high precision" that identifies only errors that really need to be prevented and maintains productivity.

Verification inspection

Accurately recognize and match letters and numbers.

Search

Search for characters within the inspection area and cut out each character as a single image.

Forcibly cut out numbers that are close together.

Recognition

The cut out characters are recognized as a dictionary. In addition, for numbers that are likely to be misread, we check all number dictionaries to ensure accurate identification and detect errors.

Verification

It understands the character string that should come and accurately inspects it by comparing the read string with the match string.

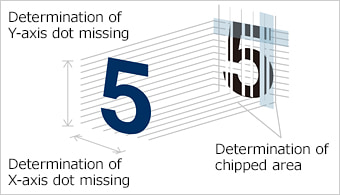

Missing character inspection

Determines and judges missing print from multiple angles and controls excessive error reactions.

Determination of missing dot

Determination of chipped area rate

Inspection machine monitor-less specification when printer is installed at the same time

When simultaneously installing our printer compatible with the color touch panel controller "EUI2+" and the print inspection machine "PCi series", the inspection operation screen can be displayed and operated using "EUI2+", so there is no need for an inspection machine monitor. Contributes to space saving and improved work efficiency through centralized management.

Specification

| Model | PCi500 |

|---|---|

| Type | High-performance date print inspection system |

| Inspection system | Character verification (verification test against registered characters) |

| Camera | Camera color CMOS camera (400,000 pixels) |

| Number of cameras that can be connected | Up to 2 units |

| Number of pixels | 512 x 480 pixels |

| Image Processing | Gray processing / Binarization |

| Power supply | AC100-230 V, 100 VA, 50/60 Hz |

| Body dimensions (mm) | 183(W) x 127.5(H) x 210.5(D) ※Not included protrusions |

| Equipment configuration | Body / Monitor / Camera / Strobe |

| Operating environment | Temperature : 5℃-40℃ Humidity : Under 90%RH (no dew condensation) |

※The specification may differ from conditions of use. Specification and other information are subject to change without notice.

PCi500 configuration content

Camera installation example